Tutorial: Vreeman et al. (2002) - DC casting of a binary Al-Cu alloy¶

This tutorial describes the steps to pre-process, run and post-process an axisymmetryc direct chill (DC) casting case that corresponds to the binary Al-Cu alloy casting experiment described in Vreeman et al. (2002) with directChillFoam.

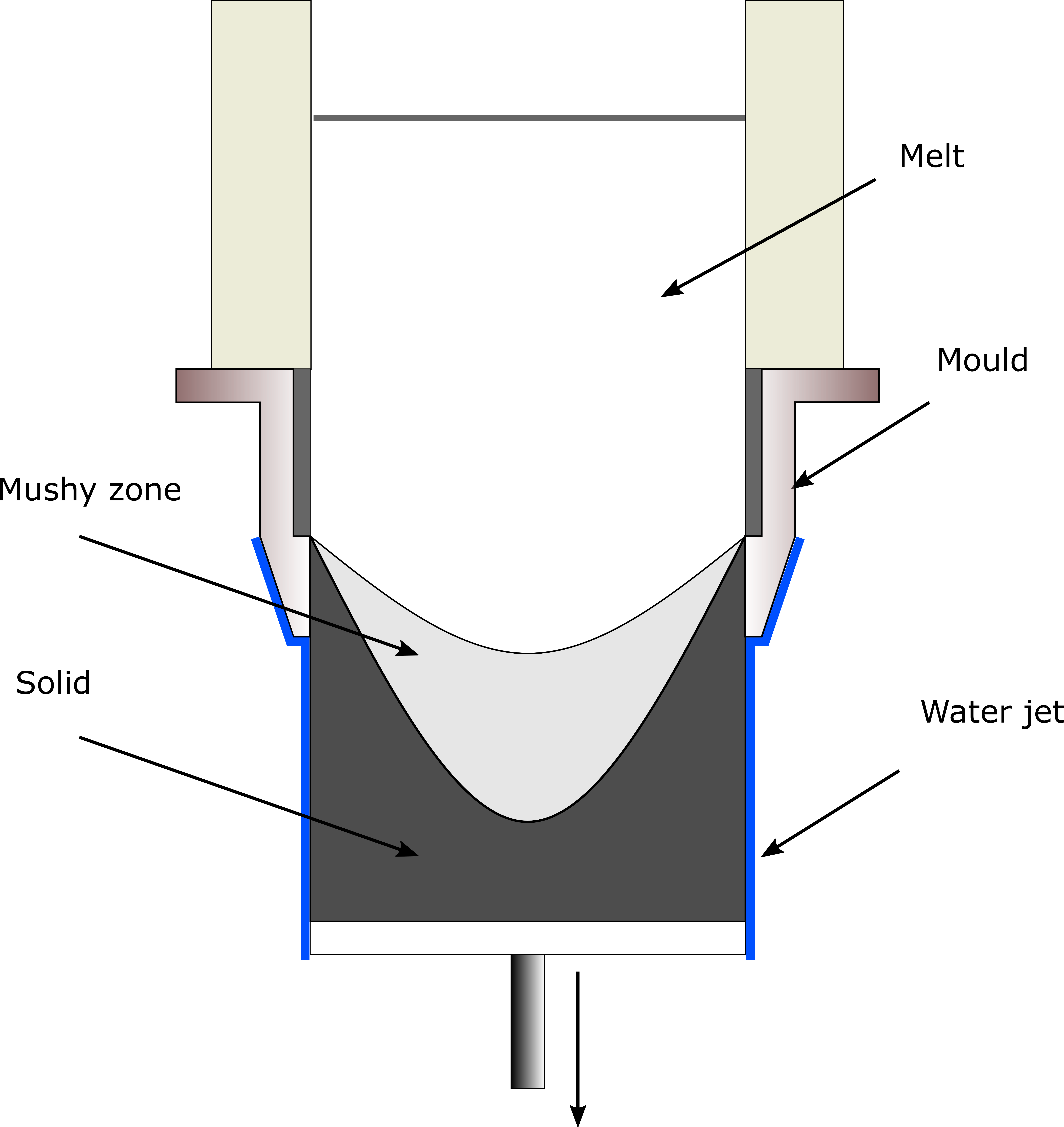

Fig. 1 The DC casting process: the melt in contact with the mould solidifies and the billet is pulled downwards by gravity as the ram is lowered. Water is sprayed at the sides of the billet providing the direct chill.¶

The execution time of this tutorial case is around 15 minutes when run in serial on a node with a 2.10 GHz processor.

Pre-processing¶

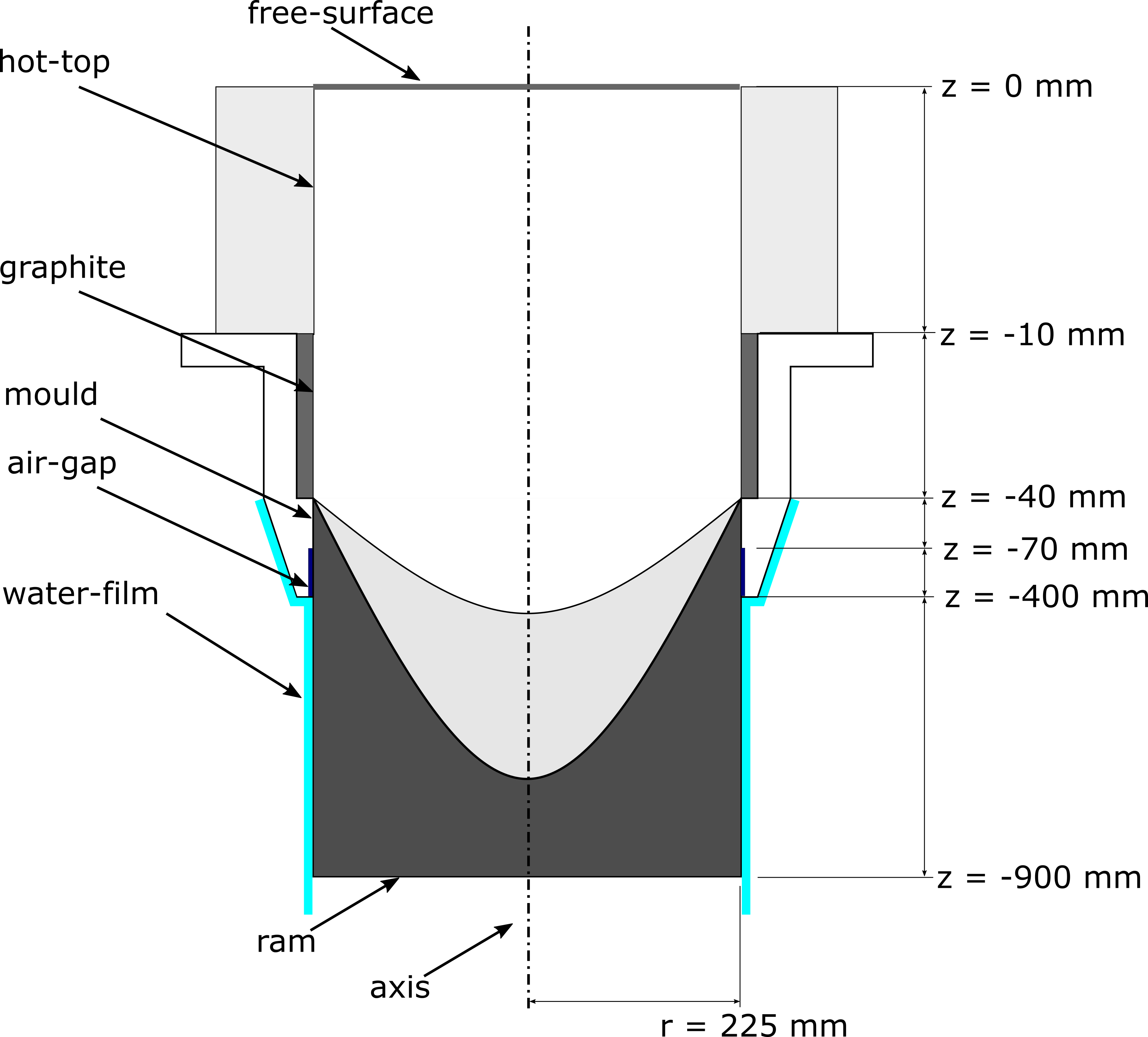

The schematic for the DC casting setup of this case is as follows:

Fig. 2 Boundary patch labels and dimensions of the casting mould and billet. The image is not drawn to scale.¶

The first step is to generate the mesh for the case and setup the boundary conditions.

To run the pre-processing steps, change to the case directory.

$ cd directChillFoam/tutorials/heatTransfer/directChillFoam/Vreeman2002

Mesh generation¶

The dictionary file that describes the mesh is located in the system directory.

$ cd system

Generate the blockMeshDict file using the Vreeman2002.system.cylinder.write_blockMeshDict() function from the system/cylinder.py script.

$ python3 cylinder.py

The axisymmetryc mesh consists of a slice of a cylinder that matches the billet dimensions. The z_points tuple list the vertices z coordinates as defined in Fig. 2. The patch names are entered in the faces list in the Vreeman2002.system.cylinder.write_boundary() function.

Return to the case directory and generate the mesh using blockMesh.

$ cd ..

$ blockMesh

Boundary and initial conditions¶

To speed up the simulation, initialize the fields with rough estimates of temperatures (and corresponding liquid fractions) in the case directory:

$ setFields

Warning

The liquid fraction values must match the temperatures for the alloy according to the constant/tStar Foam table. Otherwise, the case can diverge.

Solute¶

The solute field is dimensionless:

dimensions [0 0 0 0 0 0 0];

The field is initialized with a constant value:

internalField uniform 0.06;

The inlet boundary condition is a fixed value (stored in internalField):

free-surface

{

type fixedValue;

value $internalField;

}

All other boundaries are treated with a zero gradient condition.

Temperature¶

The mould uses the mould HTC boundary condition:

"(mould|air-gap)"

{

type mouldHTC;

mode coefficient;

h1 uniform 1250.0;

h2 uniform 40.0;

Ta constant $waterTemp;

kappaMethod fluidThermo;

relaxation 1.0;

value uniform $waterTemp;

}

The surface of the billet that is sprayed with water jets uses the water film HTC boundary condition.

Use the Vreeman2002.write_htc.write_HTC_T() function to generate the Foam temperature-htc table.

- Vreeman2002.write_htc.write_HTC_T(htc_file='constant/HTC_T', func=<function rohsenhow>, T_water=372.8)

Writes the temperature-HTC foam file using the prescribed formula.

- Parameters

htc_file (str) – Relative path of HTC foam file.

func (function) – HTC function (Rohsenhow or Weckmann-Niessen).

T_water (float) – Temperature of water jet [K].

- Returns

0 if successful.

- Return type

int

water-film

{

type waterFilmHTC;

mode coefficient;

htc

{

type table;

format foam;

file "constant/HTC_Tw";

outOfBounds clamp;

interpolationScheme linear;

}

Ta constant $waterTemp;

kappaMethod fluidThermo;

relaxation 0.3;

value uniform $waterTemp;

}

Velocity¶

The casting velocity \({U}\) is prescribed at the mould and water-cooled surface using a coded function:

"(graphite|mould|air-gap|water-film)"

{

type codedFixedValue;

value $internalField;

redirectType movingShell;

name movingShell;

code

#{

// Initialize velocity with zeroes

vectorField U(patch().size(), vector(0, 0, 0));

// Find liquid fraction

const scalarField& fL = this->patch().lookupPatchField<volScalarField, scalar>("melt1_alpha1");

// Go through all face centres

const vectorField& centre(patch().Cf());

forAll(centre, i)

{

U[i].z() = -0.001*(1-fL[i]);

}

// Apply the calculated velocities

operator==(U);

#};

codeInclude

#{

// #include "fvCFD.H";

#};

}

The values are initialized at the casting speed in m s-1.

Solid velocity¶

The movingShell coded function from the liquid velocity boundary condition is reused for the solid velocity \({U_s}\) boundary prescription:

"(graphite|mould|air-gap|water-film)"

{

type movingShell;

value $internalField;

}

The values are also initialized at the casting speed in m s-1.

Physical properties¶

Transport properties¶

The transport properties are prescribed in the constant/transportProperties dictionary file. All values are in SI units. These values are available for the alloy that is being studied either in engineering tables or by calculating them using a CALPHAD software package.

Example usage:

g_env [ 0 0 0 0 0 0 0 ] 0.7; // Coherency fraction

rho1 [ 1 -3 0 0 0 0 0 ] 1750; // Solid density

rho2 [ 1 -3 0 0 0 0 0 ] 2490; // Liquid density

mu1 [ 1 -1 -1 0 0 0 0 ] 1.28e-3; // Not required, but implementation requires a non-zero value

mu2 [ 1 -1 -1 0 0 0 0 ] 1.28e-3; // Dynamic viscosity (of liquid)

DAS [ 0 1 0 0 0 0 0 ] 1.85e-4; // Dendrite arm spacing

Thermophysical properties¶

The thermophysical properties are prescribed in the constant/thermophysicalProperties dictionary file.

Solute properties¶

The solute properties are prescribed in the constant/soluteProperties dictionary file.

Example usage:

solutes

(

Cu

{

D_l 5.66e-09; // Liquid mass diffusion coefficient

kp 0.171; // Partition coefficient

C0 0.06; // Initial solute concentration

Ceut 0.32; // Eutectic concentration

beta -7.3e-3; // Solute expansion coefficient

}

);

Note

These values are also obtained from engineering tables or by calculating them using a CALPHAD software package.

Solidification properties¶

The solidification properties are prescribed in the constant/fvModels dictionary file.

Example usage:

melt1

{

type mushyZoneSource;

active yes;

mushyZoneSourceCoeffs

{

selectionMode all;

Tliq 913.13; // Liquidus temperature [K]

Tsol 820.98; // Solidus temperature [K]

L 392000.0; // Latent heat of fusion [J/kg]

g_env 0.7; // Coherency fraction

relax 0.2; // Under-relaxation factor [0-1] - keep this value low if simulation is unstable

castingVelocity (0 0 -0.001); // Casting velocity [m/s]

tStar

// liquid fraction-temperature table

{

type table;

format foam;

file "constant/tStar";

outOfBounds clamp;

interpolationScheme linear;

}

thermoMode thermo;

rhoRef 2573.; // Reference (solid) density [kg/m^3]

beta 2.25e-5; // Thermal expansion coefficient [1/K]

phi phi; // Name of flux field

Cu 1.0e+05; // Mushy region momentum sink coefficient [1/s]

q 1.0e-06; // Carman-Kozeny model coefficient

}

}

Note

These values are also obtained from engineering tables or by calculating them using a CALPHAD software package.

The tStar table can be obtained using a CALPHAD calculation using an appropriate diffusion model e.g. the lever rule or the Scheil equation. When using a non-linear model, use small (liquid fraction) steps of the order of 0.001 if the energy solver diverges.

Control¶

The solidification and other associated libraries must be included in the system/controlDict dictionary file.

libs (

"libmyFvModels.so"

"libmyFvConstraints.so"

"libmythermophysicalTransportModels.so"

);

Discretization and solver settings¶

Discretization schemes are entered in the system/fvSchemes dictionary file. Upwinding is recommended for the solute equations.

divSchemes

{

...

div(phi,C.Cu) bounded Gauss upwind;

}

The number of energy corrector loops is prescribed in the PIMPLE entry of the system/fvSolution dictionary file.

PIMPLE

{

...

nEnergyCorrectors 3;

}

Run the application¶

Once the case has been setup, run directChillFoam in the case directory:

$ cd directChillFoam/tutorials/heatTransfer/directChillFoam/Vreeman2002

$ directChillFoam

Post-processing¶

Contour plots¶

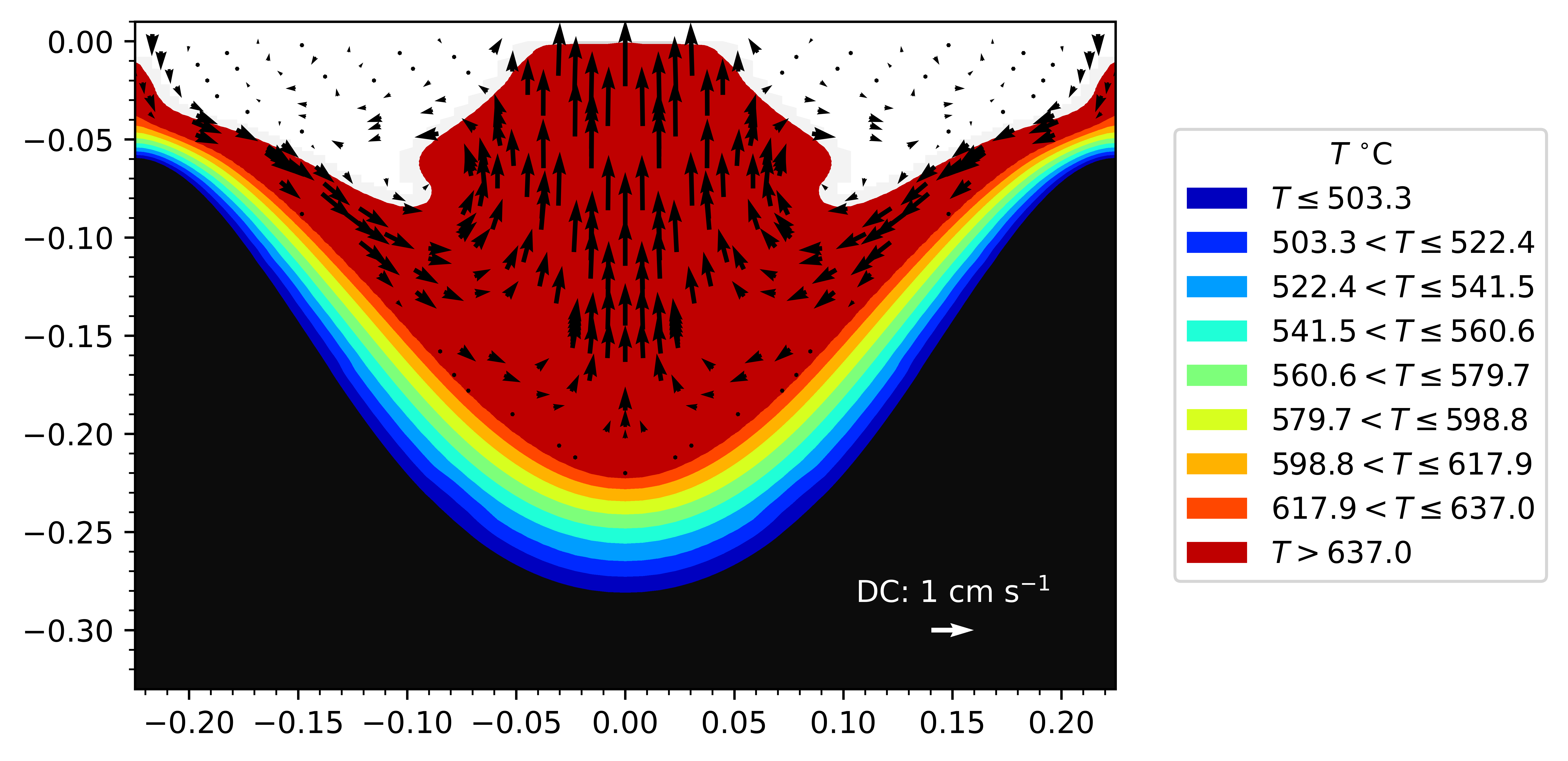

The sump profile (Fig. 3) can be plotted from the VTK files that are saved in the

postProcessing directory using the Vreeman2002.plot_sump.plot_sump() function.

- Vreeman2002.plot_sump.plot_sump(image_name='sump.png', cmap='jet')

Plots sump contour.

- Parameters

image_name (str) – Filename of image, including path.

cmap (str or matplotlib.colormaps) – Color map for plotting contour.

- Returns

0 if successful.

- Return type

int

Fig. 3 Predicted sump profile.¶

Validation¶

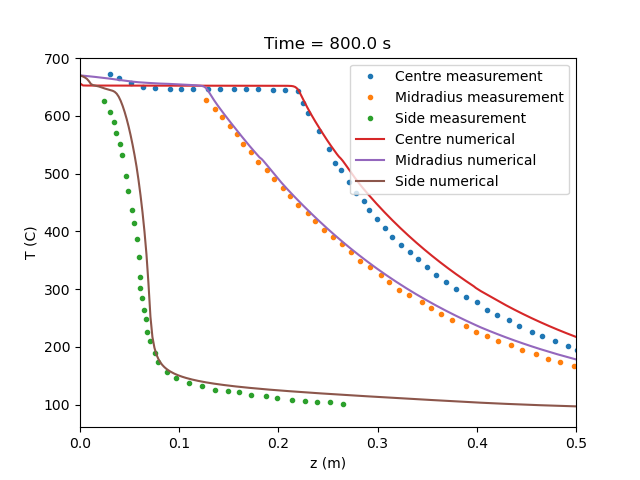

The simulation can be verified by comparing the predicted temperatures at the

billet centre line, mid-radius and surface with experimental measurements. Use

the Vreeman2002.plot_line.plot_line() function to plot Fig. 4:

- Vreeman2002.plot_line.plot_line(plot_time, Experimental, Image_Path='.')

Plots temperature graphs at plot_time.

- Parameters

plot_time (str) – Time at which to plot the temperatures.

Experimental (pandas.Dataframe) – Dataframe containing experimental data.

Image_Path (str) – Absolute path of line plot.

- Returns

0 if successful.

- Return type

int

Fig. 4 Comparing the predicted temperatures (solid lines) with experimental data (markers).¶